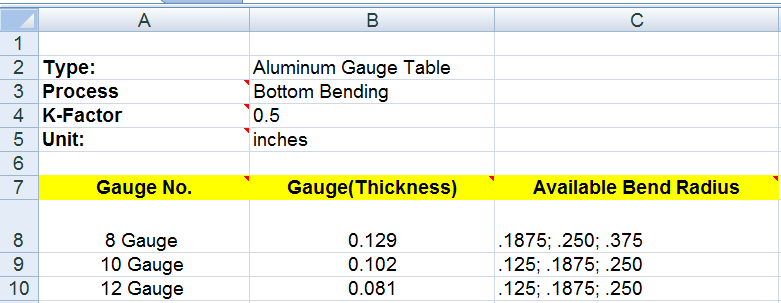

The bend radius you select may not be available if the geometry of the part will not allow us to bend with the specific tooling required to achieve that radius.

Bending radius aluminium sheet.

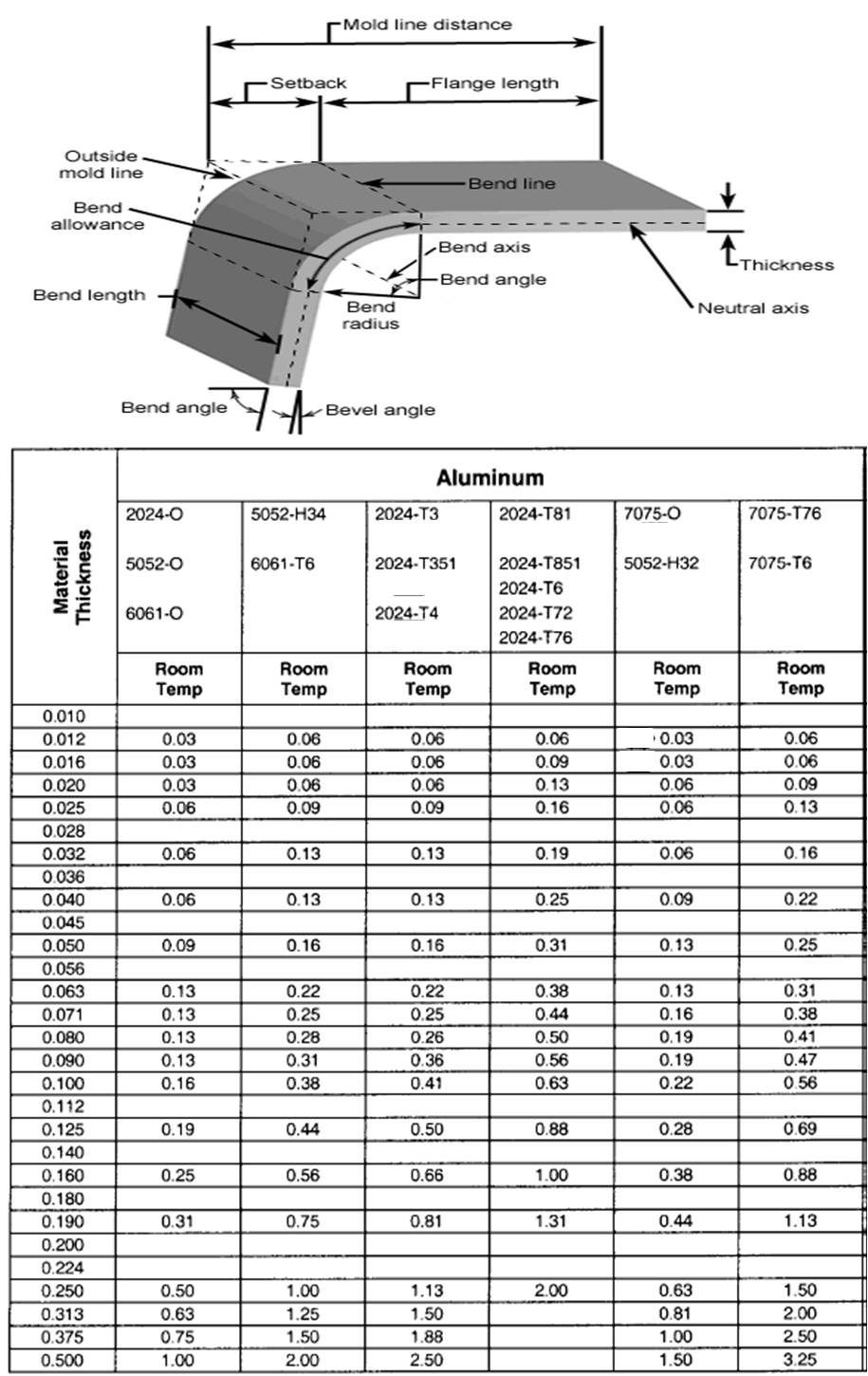

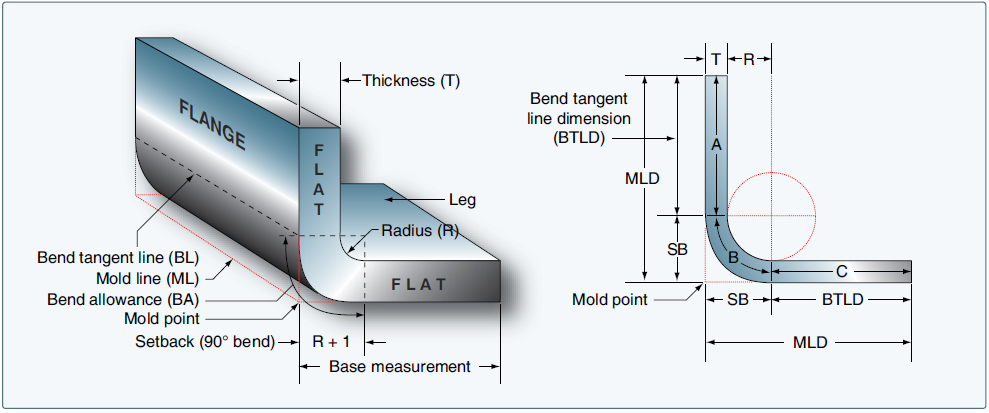

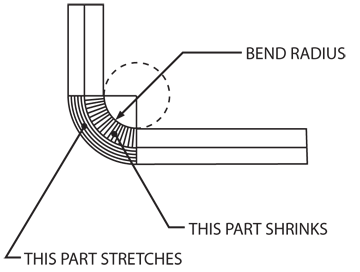

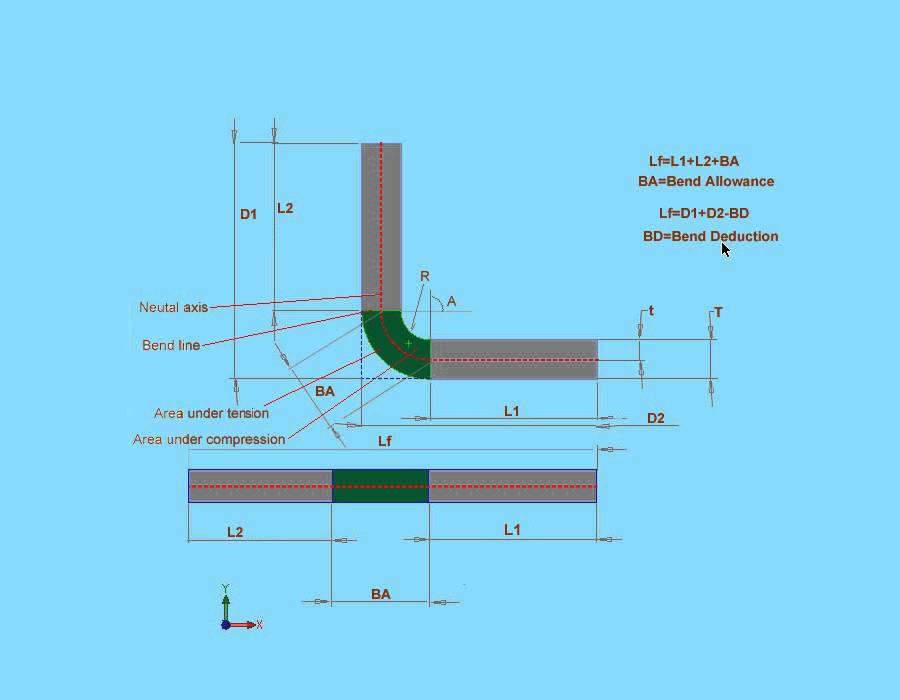

The bend deduction is the amount the sheet metal will stretch when bent as measured from the outside edges of the bend.

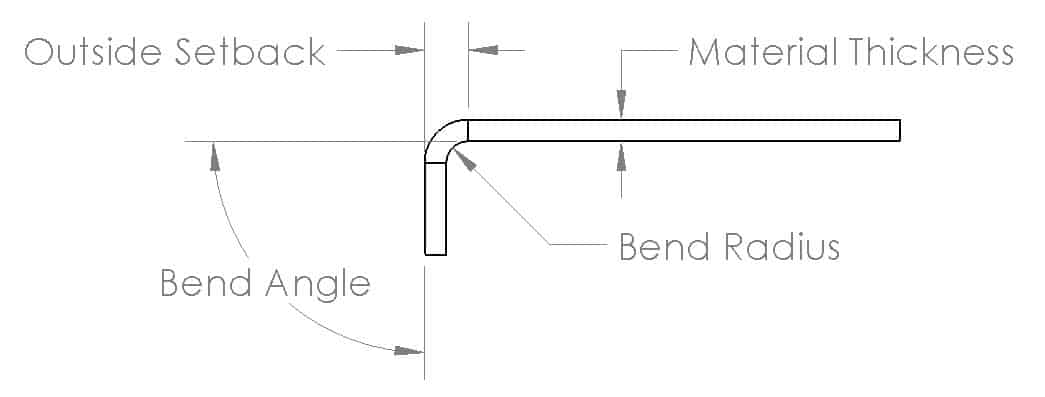

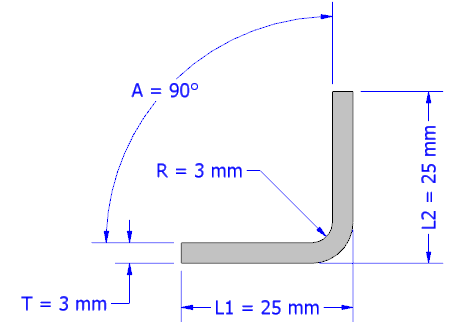

The bend radius refers to the inside radius.

Minimum sheet metal flange bend length is required to avoid cracks in the bending area.

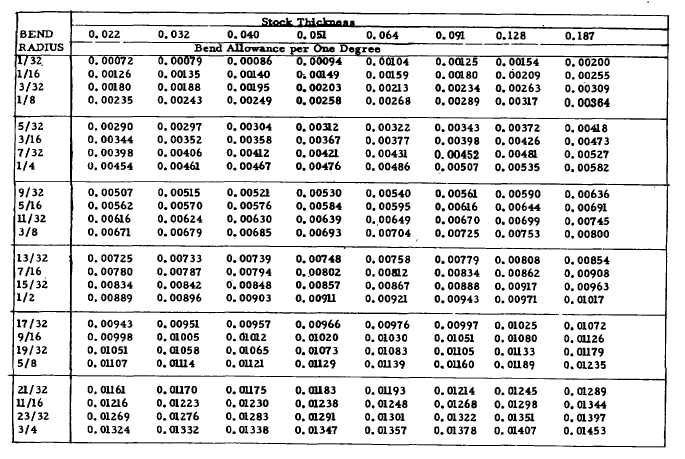

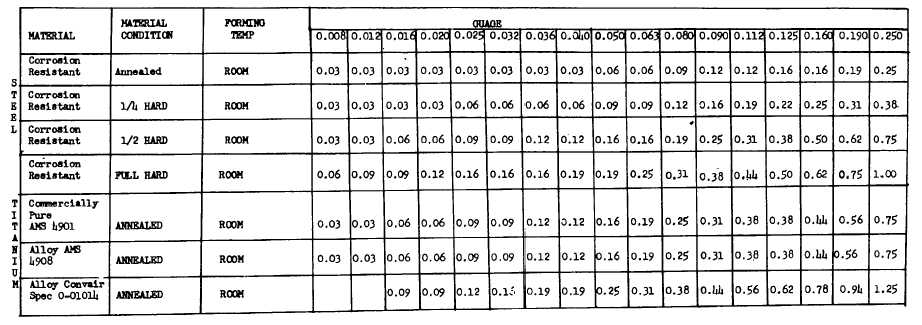

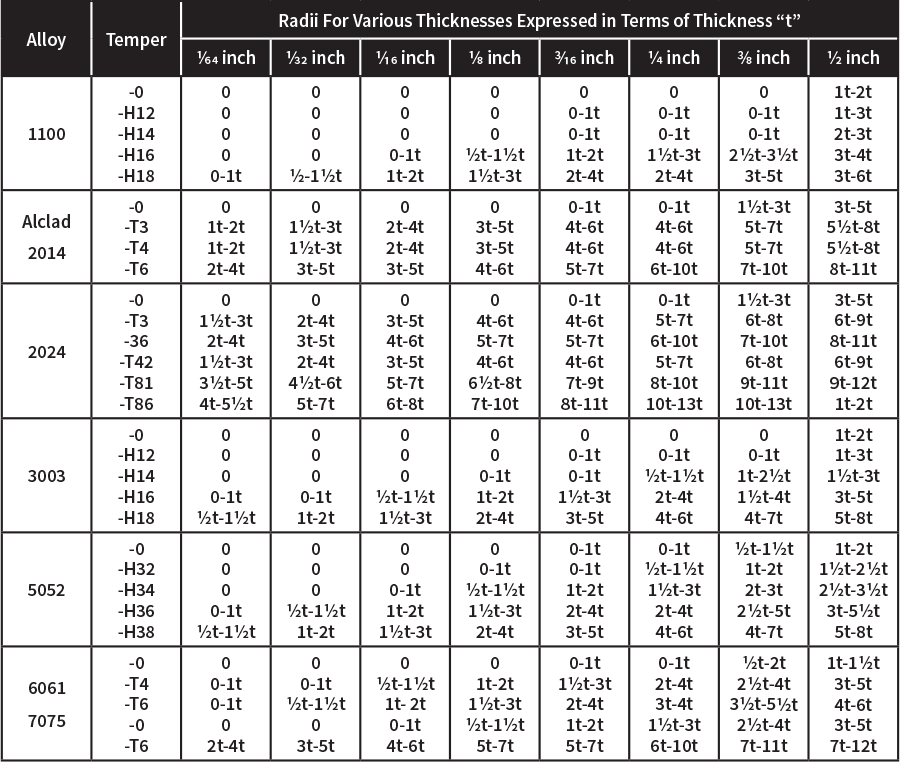

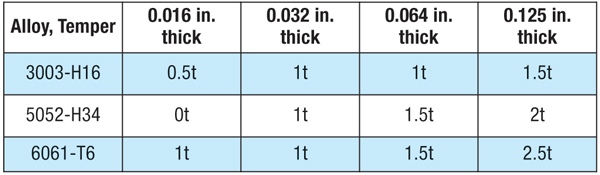

The minimum bend radius data shown in these charts is measured to the inside of the bend.

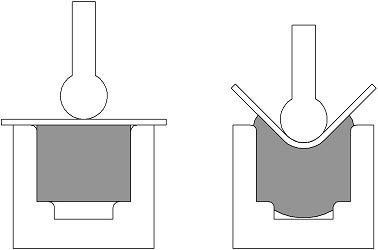

Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape.

The formed bend radius is dependent upon the dies used the material properties and the material thickness.

Radii for various thicknesses expressed in terms of thickness t.

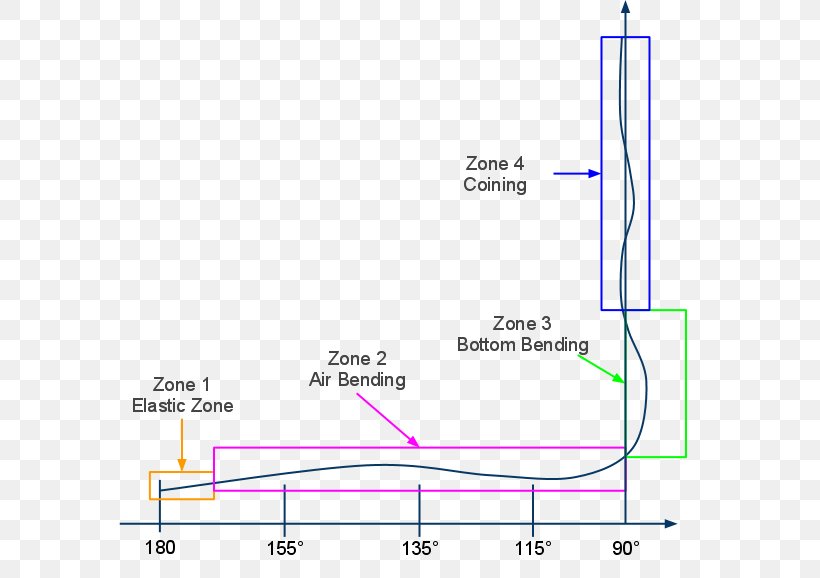

Bending is a stamping process that uses pressure to force the material to plastically deform.

When sheet metal is bent it stretches in length.

Aluminum minimum bend radii for 90 degree cold forming of sheet and plate.

Steel american iron and steel institute 1 see aisi s fabrication guidlines for cold bending thk 6061 t6.

Per the aluminum association inc.

Minimum sheet metal bend length recommendations.

Aluminum where necessary 5052 h32 may be bent to 1t and 6061 t6 to 1 1 2t.

Purchase a metal bending brake online or at your local hardware store.

For most applications with stainless steel or aluminum you can get away with a zero radius bend on anything under 0 050 thick.

Commonly used bends include v bend z bend offset bend and hemming bend etc.

Bend radius throughout the sheet metal design is kept constant to take the advantage of using the same tool during manufacturing.

This is done through the application of force on a workpiece.

The sheet metal bending height should be at least 2 times the thickness of the sheet metal plus the bending radius that is h 2t r.

Minimum recommended sheet metal bend length.

If you re bending 0 020 thick material use a 0 020 radius.

The bend radii listed are standard minimum if manufacturing for aircraft and aerospace applications.

Thereby forming a certain angle and curvature shape.

Bending is one of the most common sheet metal fabrication operations.

The force must exceed the material s yield strength to achieve a plastic deformation.

A bending brake is a specialized metalworking tool used to create precise linear bends and folds in light gauge sheet metals like the kind used to make flashing for doors windows and roofs.