The small ratio of beryllium to copper creates a family of high copper alloys with strength as high as alloy steel.

Beryllium copper sheet uk.

Beryllium is used in industry in three main forms as beryllium metal as beryllium.

Beryllium alloys are classified into two types.

Browse our beryllium copper stock items in alloy 172 annealed quarter and half hard tempers from 0 003 to 0 060.

Beryllium is a lightweight strong steel grey metal and its oxide beryllia is a hard white ceramic.

Quantity as per customer requirement.

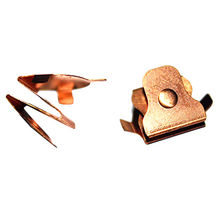

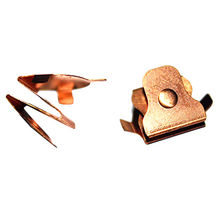

Copper beryllium alloy is commonly used to make bushings bearings and springs.

Busby metals supplies copper beryllium in a range of tempers and in strip rod bar wire.

Since the company was established in 1986 we have become market leaders in the uk but have also established a reputation to supply customers worldwide when delivery and service are of prime importance.

Beryllium is also found as a trace metal in slags and fly ash.

Beryllium copper becu also known as copper beryllium cube beryllium bronze and spring copper is a copper alloy with 0 5 3 beryllium and sometimes other elements.

Grade 17200 alloy 25 in sizes from 3mm to 100mm and up as per customer requirement.

Beryllium copper combines high strength with non magnetic and non sparking qualities.

Where is it found.

Buy online or contact us for a quote.

Copper beryllium alloys are 97 copper containing up to 3.

It has excellent metalworking forming and machining properties it has many specialized applications in tools for hazardous environments.

Get a fast quote.

Valued for their non magnetic and non sparking qualities copper beryllium alloys are available as high strength and high conductivity alloys.

Ngk berylco uk ltd are stockists of beryllium copper alloys.

The first of the two families c17200 and c17300 includes high strength with moderate conductivity while the second family c17500 and c17510.

High beryllium content up to 30 beryllium and low beryllium content 2 3 beryllium.

The commercial grades of beryllium copper contain 0 4 to 2 0 percent beryllium.

No cut fees no minimums and fast delivery nationwide.

The high strength of copper beryllium alloys is accomplished by either age hardening or precipitation hardening.

Whilst 70 30 has greater salt water resistance and strength 90 10 is more common as it is less expensive with overall good properties for a range of applications.

Request a quick quote for more details.