1 the anisotropy of young s modulus of copper sheet subjected to forward cold rolling to a reduction of 70 is determined primarily by the fourth harmonic of the expansion of the modulus curve.

Copper sheet rolling temperature.

The copper forming process.

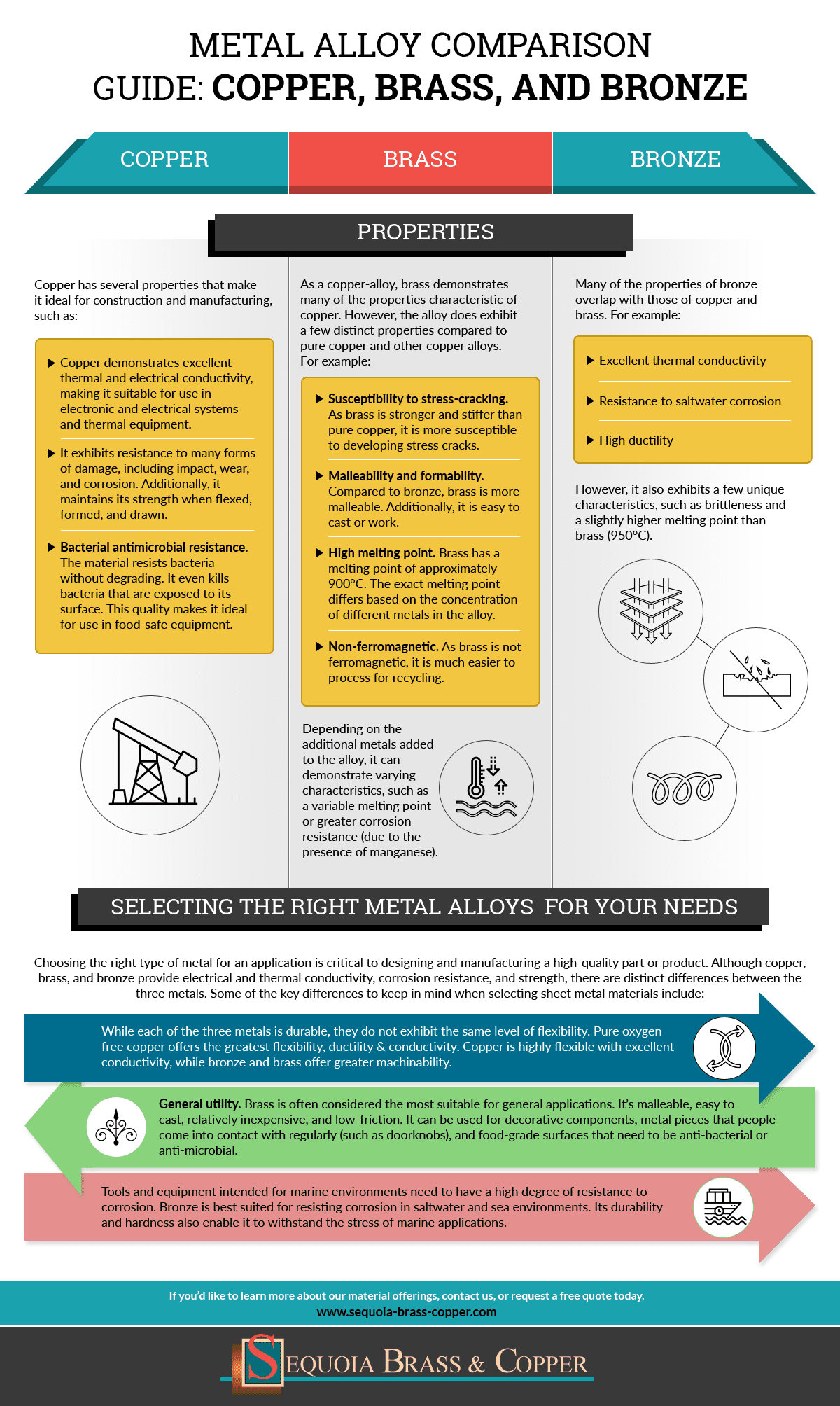

No other touch surface material has this kind of registration.

The recrystallization temperature is that temperature at which the crystal lattice structure of the metal.

The metal anneals at the brazing temperature and properties normal for the hard condition are lost.

Copper is the only solid surface material registered by the u s.

Below is a quick guide to help you determine which thickness best suits the needs of your project.

This booklet will serve to answer immediate questions about using copper and copper alloys in familiar ways and in.

Environmental protection agency to continuously kill bacteria that pose a threat to human health.

The deformation zone state of stress and angle of contact in rolling is shown in fig.

Load and power requirement for rolling.

2 4 simple rolling of a plate.

Iii temperature of rolling.

If the temperature of the metal is above its recrystallization temperature then the process is.

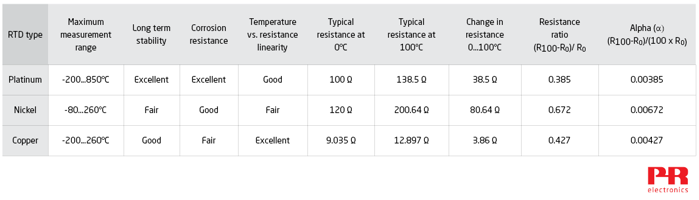

Additional information on physical properties and cold rolled tempers is available in data sheets from material suppliers asm metals handbook volume 2.

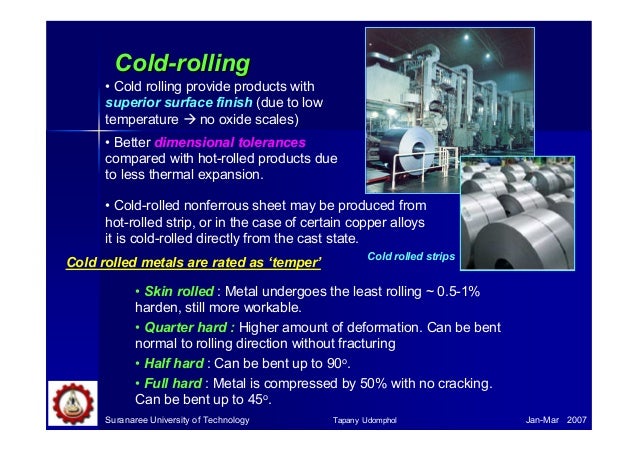

Cold rolling used to make sheet strip and foil.

Traditional techniques involve cutting out copper sheet to form the sidewall forming it to cylindrical shape and making a joint.

In older processes the concentrate containing between 5 and 10 percent water is first roasted in a cylindrical refractory lined furnace of either the hearth or.

Iv speed of rollers etc.

Table indicates the recommended maximum angle of bite α for different rolling processes.

This process is mainly suited for low carbon steel.

Hot rolling is carried out at temperatures above the recrystallization temperature of the metal.

Once a concentrate has been produced containing copper and other metals of value such as gold and silver the next step is to remove impurity elements.

The material is heated up to a temperature just below the lower critical temperature of steel.

The temperature range for process annealing ranges from 260 c 500 f to 760 c 1400 f depending on the alloy in question.

In metalworking rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness and to make the thickness uniform.

The unit of measurement used to identify the thickness of a sheet of copper varies e g gauge mil ounces per square foot inches millimeters.

The concept is similar to the rolling of dough rolling is classified according to the temperature of the metal rolled.

A complete listing of temper designations and descriptions for copper and copper alloys cane found in astm b601 standard practice for temper designations for copper and copper alloys wrought and cast.

Handles and lids are fitted as needed.